The Keestrack S5 Tracked Stacker is a high-productivity stacking machine that can stack piles of processed material up to 9.3m high or 15,000 tonnes of rock. The S5 Stacker aids a quarry's production, efficiency, and competitiveness by reducing loader movements and labour requirements.

All Keestrack Diesel-Hydraulic mobile machines integrate their signature Load Sensing Pump Technology. Whilst traditional mobile plant use gear pumps and restrictors, Keestrack's Load Sensing Pumps do just as the name says, they sense how much fluid is needed to run the plant to what the operator has configured.

Compared to the aforementioned gear pumps, Load Sensing Pumps save businesses up to 25% on their Diesel Burn, a significant economic and environmental saving, best yet their just as reliable as the traditional gear pump and have reduced wear as hydraulic componentry is not oversupplied.

Keestrack is one of the foremost leaders in Quarry equipment electrification. Their E-Series equipment features an all-electric drive system and an integrated Diesel Generator for off the grid running.

By utilising E-Motors over traditional hydraulic motors and engine direct drives, E-Series machines have higher output power with less energy consumption in addition to a longer operational life span.

The E-Series onboard Diesel Genset provides the necessary power to run the machine off the main grid and delivers a 50% fuel saving compared to the equivalent Diesel-Hydraulic machine, as an all-electric drive system is more efficient resulting in less generated energy being lost.

When set up via 3-phase grid connection E-Series machines reach another level of cost and carbon reduction. Powered directly from the grid the energy cost is 70% less than the equivalent Diesel-Hydraulic machine, and the equipment carbon footprint is further reduced to that of the grid.

Keestrack's Wireless Remote offers more than just a convenient way to start and stop the machine, it's a fully-featured platform giving operators full control of the machines and its functions from the comfort and safety of the cab.

The Wireless Remote enables start and stop, tracking,and adjustment of machine-specific parameters like C.S.S on a Jaw and Aprons onan Impactor. It also includes an emergency stop switch, making it an extension of the machine's safety systems.

The Wireless Remote has 2-way communication with the plant, enabling the remote to display the machines current configuration and what the operator is adjusting.

Like your cellphone, the Wireless Remote is USB rechargeable and is securely paired with the machine. Built from a weather-sealed polycarbonate hardshell it also incorporates a rubberised grip for impact protection.

The Keestrack-er Remote Telematics System is an advanced monitoring system that allows monitoring and remote adjustment of any PLC monitored components.

The PLC is connected to a cellular telematics modem, the unit stores and transmits the data to the Keestrack-er cloud, where the owner or service agent can access the telemetry.

If an area with no signal the telematics unit will upload the stored data once back in range. Keestrack-er offers some distinct advantages for fleet management. Allowing managers to see where the equipment is positioned on the site via a map overlay and how productive the mobile plant has been.

Metrics like fuel usage, engine load, crushing/screening parameters, conveyor parameters are all monitored and recorded, allowing managers to see real-time and historical data.

In addition to tracking a mobile plants productivity, the Keestrack-er Telematics System enables equipment to be remotely diagnosed and adjusted by Equip2, helping solve production issues using data.

13,000kg

2,290mm

12,000mm

2,760mm

DEUTZ TD 2.2; L3 edg - 30kW

Tier 4i, EU Stage IIIA

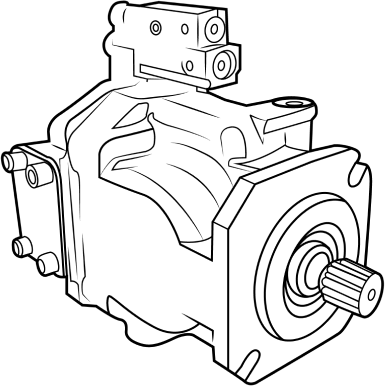

45ccm Load Sense Pump + 25ccm Manual Pump

1,400 - 3,050mm

1,880mm

2,200mm

23,000mm

1,000mm

9,350mm

You'd agree that buying equipment should be easy, and the machine you purchase is fit for purpose. After all, purchasing equipment can be a large capital expenditure and not a decision you take lightly, you need to know that the business you're purchasing from will sell you the right piece of equipment, and support that equipment.

The Equip2 flywheel is our unique approach to equipment procurement and support. Each pillar supports the other and ensures the continued success of businesses using Equip2 as their processing solutions partner.

For many purchases you make, whether personal or business, you likely place a high value on the service you receive. And as we all conclude, the bigger the investment, the higher level of service we expect.

If it's anything we focus the most effort on, it's service. We recognise that great service is also great sales, and service is what keeps machines running profitably. We take a lot of pride in having all fields of expertise in-house so we can support businesses whether they're investing in new equipment, day to day operations or trying to improve their overall efficiency and profitability.

For many purchases you make, whether personal or business, you likely place a high value on the service you receive. And as we all conclude, the bigger the investment, the higher level of service we expect.

If it's anything we focus the most effort on, it's service. We recognise that great service is also great sales, and service is what keeps machines running profitably. We take a lot of pride in having all fields of expertise in-house so we can support businesses whether they're investing in new equipment, day to day operations or trying to improve their overall efficiency and profitability.

For many purchases you make, whether personal or business, you likely place a high value on the service you receive. And as we all conclude, the bigger the investment, the higher level of service we expect.

If it's anything we focus the most effort on, it's service. We recognise that great service is also great sales, and service is what keeps machines running profitably. We take a lot of pride in having all fields of expertise in-house so we can support businesses whether they're investing in new equipment, day to day operations or trying to improve their overall efficiency and profitability.

For many purchases you make, whether personal or business, you likely place a high value on the service you receive. And as we all conclude, the bigger the investment, the higher level of service we expect.

If it's anything we focus the most effort on, it's service. We recognise that great service is also great sales, and service is what keeps machines running profitably. We take a lot of pride in having all fields of expertise in-house so we can support businesses whether they're investing in new equipment, day to day operations or trying to improve their overall efficiency and profitability.